- Industry-first, gel-free ADSS cable for cleaner, faster and less costly deployments

- Efficient, cost-effective solution for short cable spans ranging up to 1,500 feet (460 meters) ¹

- Custom engineered per application

- Lighter weight, gel-free cable helps reduce cable end preparation time ²

- May enable significant cost savings from the use of less costly attachment hardware ³

- Allows up to a 10% greater span length capability 4

- Fiber counts up to 288

- Cleaner work environment helps support faster splicing with higher yields

- Environmentally-friendly cable helps reduce waste and the need for special cleaning solvents

- Single cable outer diameter for fiber counts of 2 to 60 for simplified hardware selection and splicing

- Available with Lightera application-specific fibers including AllWave® Zero Water Peak (ZWP) and AllWave+ Single-Mode, TrueWave® RS Low Water Peak (LWP) and Multimode Fibers

- Highly durable and reliable for power distribution networks, FTTH deployments, direct use in ducts, aerial-to-duct transitions and aerial-to-underground installations

PowerGuide® DT ADSS Cable

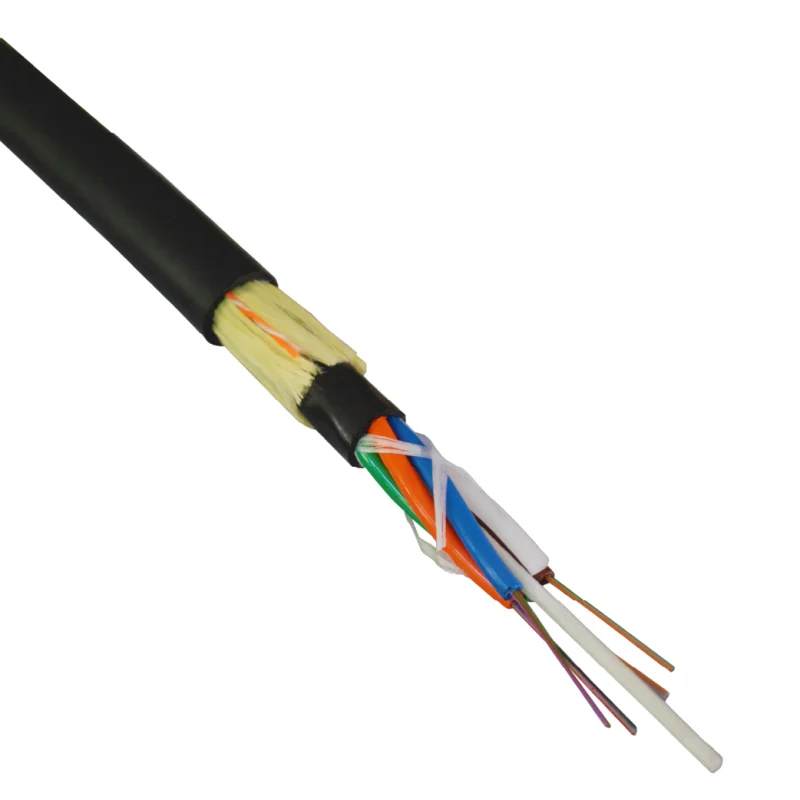

As the industry’s first completely gel-free, double jacket All-Dielectric, Self-Supporting (ADSS) Loose Tube Cable, the groundbreaking PowerGuide DT Cable helps save time and money on installation for cable spans ranging up to 1,500 feet¹ (460 meters). This outstanding, cost-effective solution is an excellent choice for power distribution networks, FTTH deployments and duct installations.

Lightera combines its leading ADSS cable design with its field-proven, gel-free loose tube cable construction to create each PowerGuide ADSS Cable. To construct this cable, optical fibers are placed in flexible buffer tubes that contain a specially-engineered, super-absorbent yarn that delivers water blocking “on demand” without the use of messy gels and filling compounds. This patented water-blocking system has been successfully deployed for a decade in our Fortex™ DT Cable product families. Next, the color-coded buffer tubes are stranded around a dielectric central member using the reverse oscillating lay (ROL) stranding technique for easy, mid-span fiber access. Additional gel-free, super-absorbent material is then applied to the cable core and an inner polyethylene (PE) jacket is added. Finally, aramid yarn strength elements and a second robust outer PE jacket are applied to complete the construction of a totally gel-free, lightweight cable that is durable, reliable and easy to handle and install.

As the industry’s first completely gel-free, double jacket All-Dielectric, Self-Supporting (ADSS) Loose Tube Cable, the groundbreaking PowerGuide DT Cable helps save time and money on installation for cable spans ranging up to 1,500 feet¹ (460 meters). This outstanding, cost-effective solution is an excellent choice for power distribution networks, FTTH deployments and duct installations.

Lightera combines its leading ADSS cable design with its field-proven, gel-free loose tube cable construction to create each PowerGuide ADSS Cable. To construct this cable, optical fibers are placed in flexible buffer tubes that contain a specially-engineered, super-absorbent yarn that delivers water blocking “on demand” without the use of messy gels and filling compounds. This patented water-blocking system has been successfully deployed for a decade in our Fortex™ DT Cable product families. Next, the color-coded buffer tubes are stranded around a dielectric central member using the reverse oscillating lay (ROL) stranding technique for easy, mid-span fiber access. Additional gel-free, super-absorbent material is then applied to the cable core and an inner polyethylene (PE) jacket is added. Finally, aramid yarn strength elements and a second robust outer PE jacket are applied to complete the construction of a totally gel-free, lightweight cable that is durable, reliable and easy to handle and install.

Features And Benefits

Image

Product Description

As the industry’s first completely gel-free, double jacket All-Dielectric, Self-Supporting (ADSS) Loose Tube Cable, the groundbreaking PowerGuide DT Cable helps save time and money on installation for cable spans ranging up to 1,500 feet¹ (460 meters). This outstanding, cost-effective solution is an excellent choice for power distribution networks, FTTH deployments and duct installations.

Lightera combines its leading ADSS cable design with its field-proven, gel-free loose tube cable construction to create each PowerGuide ADSS Cable. To construct this cable, optical fibers are placed in flexible buffer tubes that contain a specially-engineered, super-absorbent yarn that delivers water blocking “on demand” without the use of messy gels and filling compounds. This patented water-blocking system has been successfully deployed for a decade in our Fortex™ DT Cable product families. Next, the color-coded buffer tubes are stranded around a dielectric central member using the reverse oscillating lay (ROL) stranding technique for easy, mid-span fiber access. Additional gel-free, super-absorbent material is then applied to the cable core and an inner polyethylene (PE) jacket is added. Finally, aramid yarn strength elements and a second robust outer PE jacket are applied to complete the construction of a totally gel-free, lightweight cable that is durable, reliable and easy to handle and install.

Note

¹ Maximum span range from 460 feet to 1,500 feet, depending on loading conditions, fiber counts, installation conditions and clearance requirements. Contact Lightera for specific details for your application.

Why the PowerGuide DT ADSS Cable?

As the world’s first totally gel-free, double jacket ADSS cable, PowerGuide DT Cable offers the same high performance and reliability as its gel-filled counterparts. Plus, it’s completely gel-free, even inside of the buffer tubes. By eliminating gels and filling compounds, this cable helps enable substantial savings on installation time and labor costs. In fact, when compared with similar gel-filled ADSS cables, PowerGuide DT Cable can help cut cable end preparation time by up to 80%², helping to significantly reduce labor costs for splicing and terminations.

PowerGuide DT Cable also offers a significantly lower overall cable weight, which results in easier handling and lower operating tensions on the poles. This reduction in cable weight and operating tensions may also enable the use of less costly, lighter duty attachment hardware³, and allows up to a 10% greater span length capability than similar, gel-filled cables⁴. In addition, this lightweight cable is easier to handle and install, creating less of a load on your work crew and plant infrastructure.

The PowerGuide DT Cable’s gel-free design also helps save on labor costs by offering faster splicing with higher first pass yields due to a cleaner work environment. By removing all gels and filling compounds, this cable allows virtually effortless splice preparation, while keeping your tools, workspace, closures and cabinets cleaner and safer. This cable also enables additional cost savings by helping to minimize or eliminate the need for special cleaning solvents and wipes, along with the expense of cleaning splicer/cleaver equipment. These advantages combine to make PowerGuide DT ADSS Cable an “environmentally-friendly” solution that also helps save on deployment time and expense.

In summary, the PowerGuide DT ADSS Cable is an outstanding choice for power distribution networks and FTTH deployments, and for aerial use (self supporting), direct use in ducts, aerial-to-duct transitions and aerial-to-underground installations.

Note

² Based on field studies examining the time required to prepare cable ends for splicing and terminations for similar gel-filled ADSS cables as compared with PowerGuide DT Cable.

³ For a typical 250-foot cable run, under NESC Medium Loading Conditions, the gel-free cable construction allows for the use of light duty attachment hardware.

⁴ For a typical, gel-free 144-fiber ADSS cable at 500-foot span lengths under NESC Medium Loading Conditions, there can be a gain of up to a 10% increase in span length capability when compared with equivalent strength systems in similar, gel-filled cables.

⁵ Fortex DT Loose Tube Cable was a Fiber Optic Technology 2003 Tech Award Winner.

⁶ Fortex DT Loose Tube Cable was the industry’s first gel-free loose tube cable to meet the water-blocking requirements of Telcordia Technologies’ GR-20-CORE outside plant standards.

Specifications

| Specifications | |

|---|---|

| Fiber Count: | 2-288 |

| Outer Diameter – In. (mm) | Variable |

| Weight – Lb/kft (kgm/km) | Variable |

| Performance Standard | Tested Per Applicable Requirements of Telcordia Technologies Gr-20, ANSI/ICEA S-87-640, EIA/TIA, IEEE |

| Handling |

|

| Minimum Bend Radius, With Load | 15 X OD* |

| Minimum Bend Radius, With No Load | 10 X OD* |

| Minimum Bend Radius, Storage Coils | 10 X OD* |

| Maximum Rated Cable Load (MRCL): | Variable |

| Maximum Long Term Load: | Variable |

| Note | OD = Outer Diameter of Cable |

Temperature

| Temperature | |

|---|---|

| Installation | -22 °F to 158 °F (-30 °C to 70 °C ) |

| Operation | -40 °F to 158 °F (-40 °C to 70 °C ) |

| Storage | -40 °F to 167 °F (-40 °C to 75 °C ) |

You Can Rely on Lightera

PowerGuide DT ADSS Cable is the latest Lightera innovation to incorporate many of the company’s developments in gel-free fiber optic cable design. In 2003, Lightera introduced another groundbreaking cable, the award-winning 5, gel-free Fortex DT Loose Tube Cable 6. Today, with more than a decade of field-proven, gel-free cable performance in the ground and in the air, Lightera continues to demonstrate its industry leadership in innovation with the first-to-market, gel-free, double jacket ADSS cable.

Fiber Type²

| Fiber Type² | |||||||

|---|---|---|---|---|---|---|---|

| Single-Mode Fiber | Fiber (S1) | Fiber (S2) | Fiber (SF) | Fiber Standards | Wavelengths (nm) | Typical* Attenuation (dB/km) | Maximum Cable on Reel Attenuation (dB/km) |

| AllWave ZWP Fiber | 3 | B | E | G.652.D | 1310/1385/1550 | – | 0.35/0.31/0.25 |

| AllWave+ ZWP Fiber | 3 | C | E | G.652.D/G.657.A1 | 1310/1385/1550 | – | 0.35/0.31/0.25 |

| AllWave FLEX ZWP Fiber | 5 | B | E | G.652.D/G.657.A1 | 1310/1385/1550 | – | 0.35/0.31/0.25 |

| AllWave One Fiber | 3 | F | E | G.652.D/G.657.A1 | 1310/1385/1550 | 0.33/0.31/0.19 | 0.34/0.31/0.22 |

| AllWave ULL Fiber | 3 | H | E | G.652.D/G.657.B | 1310/1550 | 0.31/0.17 | 0.33/0.19 |

| TrueWave RS LWP Fiber | 6 | 2 | 6 | G.655.C&D | 1550 | 0.21 | 0.25 |

| TeraWave Fiber | 6 | 2 | R | G.654.B | 1550 | 0.19 | 0.25 |

| TeraWave ULL Fiber | 6 | 9 | R | G.654.B | 1550 | 0.18 | 0.22 |

| Multimode Fiber | Fiber (S1) | Fiber (S2) | Fiber (SF) | Fiber Standards | Wavelengths (nm) | Typical* Attenuation (dB/km) | Maximum Cable on Reel Attenuation (dB/km) |

| 62.5 µm Fiber | R | U | 9 | OM1 62.5 µm | 850/1300 | – | 3.4/1.0 |

| LaserWave FLEX 300 Fiber | L | F | 2 | OM3 50 µm | 850/1300 | – | 2.4/0.7 |

| LaserWave FLEX 550 Fiber | L | H | 2 | OM4 50 µm | 850/1300 | – | 2.4/0.7 |

Compare products and choose the best one

Compare features, sizes, models to find the perfect option for you