Fiber optic cables provide versatility and durability in a wide range of applications and are critical for ensuring the reliability of communication networks all over the world. At its most basic, a fiber optic cable is composed of glass threads (optic fibers), each of which can transmit messages modulated onto light waves. Offering greater bandwidth than copper cable, fiber optic cables have quickly become the go-to cable solution in communications, industrial networking, sensing, and avionics applications.

Fiber Optic Cable

Connecting the World

Communications

Lightera provides high-strength fiber cables for use in various industrial, indoor, and outdoor applications. Offering unique properties and benefits for different types of use, our communications fiber optic cable products can easily meet complex application requirements and specifications.

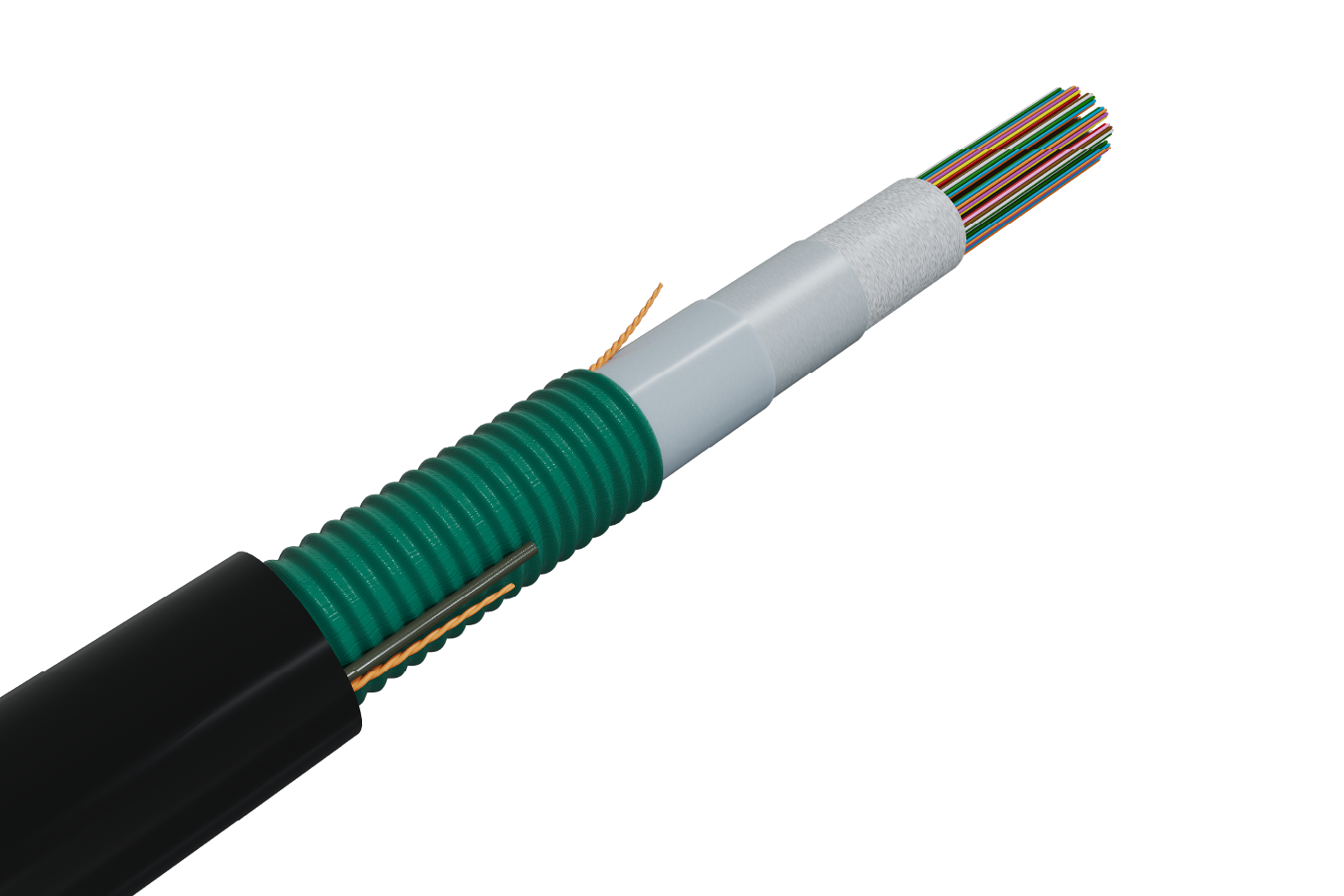

Our DryBlock® cable, for instance, is highly durable and flexible, making it ideal for outside plant (OSP) applications, including duct, direct-buried, and lashed aerial installations in harsh environments. Featuring corrugated steel armor and a polyethylene jacket, this cable provides rugged durability and rodent resistance. Lightweight and RDUP-listed, DryBlock® also allows for quick, easy installation.

Many of our products, including our ribbon cables and dry gel-free cables, are used extensively in various FTTx applications. Our EZ-Bend® cables, for instance, provide reliable connections with virtually zero loss. All of our fiber optic solutions, whether designed for FFTH (fiber-to-the-home), FFTN (fiber-to-the-node), or FFTC (fiber-to-the-curb) applications, allow for the delivery of more data — across greater distances — than traditional copper cables. Lightera fiber optic cabling is specifically designed to support today’s ever-connected world and the increasing need for high-speed broadband internet, and our versatile solutions allow for optimal quality video and seamless voice and data transmission with maximum ROI.

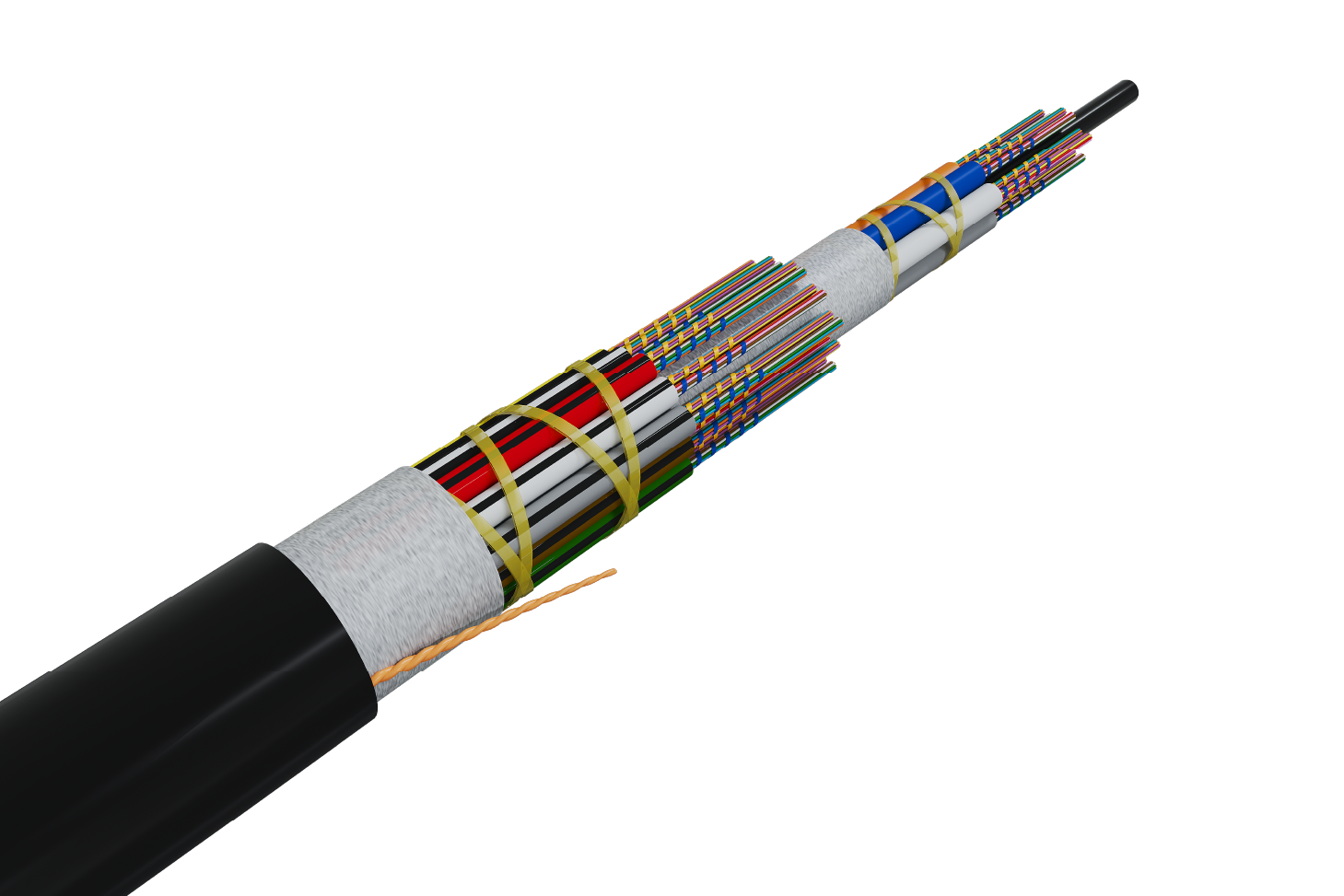

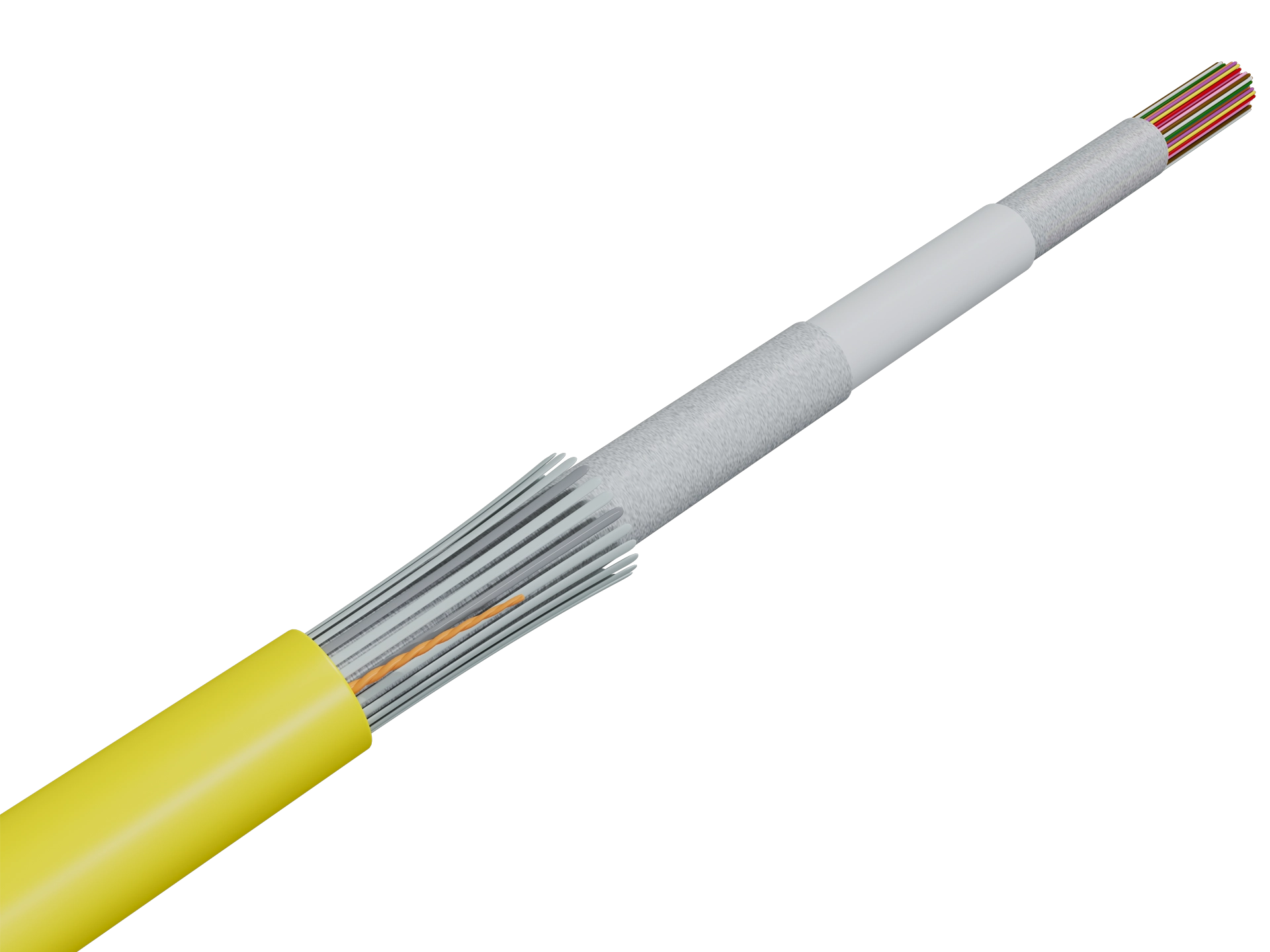

Loose Tube Cable

Innovative loose tube cables increase fiber density and make deployment easy for duct, aerial (lashed and self-supporting), direct buried, and outdoor/indoor installations.

Ribbon Cable

Lightera has led the industry in optical fiber ribbon technology by being the first to introduce fiber optic ribbon cables and the first to introduce UV-curable acrylate material ribbons. Today’s AccuRibbon® Optical Ribbons hold up to 24 colored optical fibers in a planar array, providing a high fiber density unit for use in fiber optic cabling or routing inside electronic equipment.

Our ribbon cables deliver the highest fiber density in the most compact

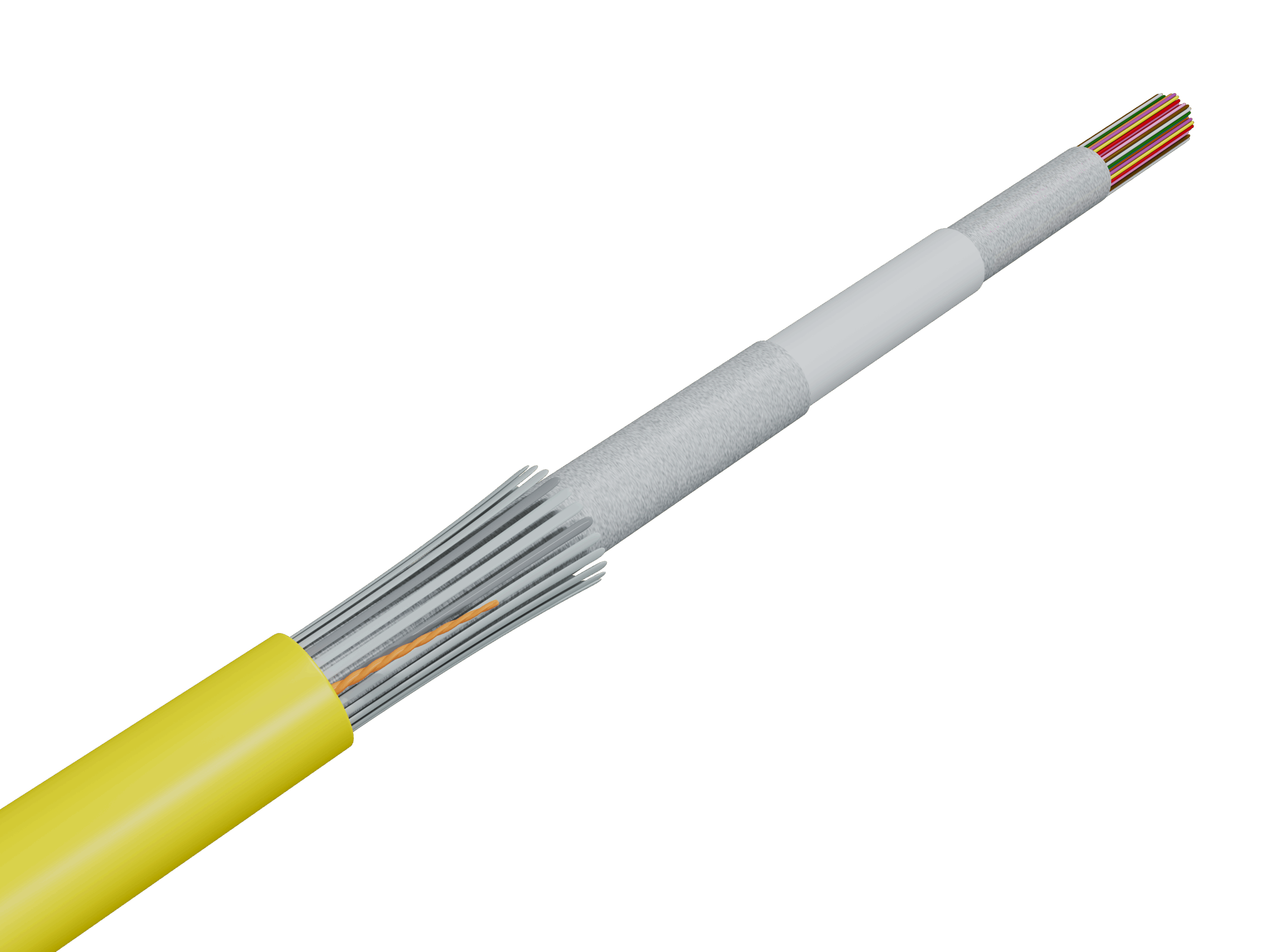

Totally Gel-Free Cable

By eliminating messy gels and filling compounds, totally gel-free cables streamline the handling and installation process for outside plant (OSP) cables for higher efficiencies. These cables are available in loose tube or ribbon constructions with dielectric or metallic sheath options.

Rollable Ribbon

Optical fiber rollable ribbons can roughly double fiber density versus using traditional outside plant cables, which makes these ribbons a very valuable tool in the network designer’s toolbox.

The fibers in a rollable ribbon are attached intermittently. This configuration makes the ribbon much more flexible and “rollable”. In addition, this design enables more fiber to be installed in less space than flat ribbon cables while also allowing the fibers to be spliced using typical ribbon splicing techniques and equipment.

While greater fiber density (more fibers in a smaller space) is a key starting point, rollable ribbon technology offers many more benefits when compared to flat ribbon cables.

Lighter weight for longer pulling/blowing distances and reduced installation costs.

Smaller coiling diameters to fit in smaller handholes.

Smaller cables enable longer lengths on a reel.

Longer lengths can reduce the number of splice points, splicing costs and shipping costs. These ribbon cables are also gel-free. While removing the gel decreases the cable weight, the main benefit is to speed up and simplify the splicing process. Taking the splicing process into account, the list of rollable ribbon benefits grows even longer.

They can be spliced using typical ribbon splicing techniques, maintaining the productivity and restoration speed benefits of ribbons.

It is easier to break out individual fibers from the ribbon structure when using rollable ribbons.

There is the potential to use smaller splice trays, which improves closure density, as rollable ribbons are not confined to a rigid flat ribbon structure.

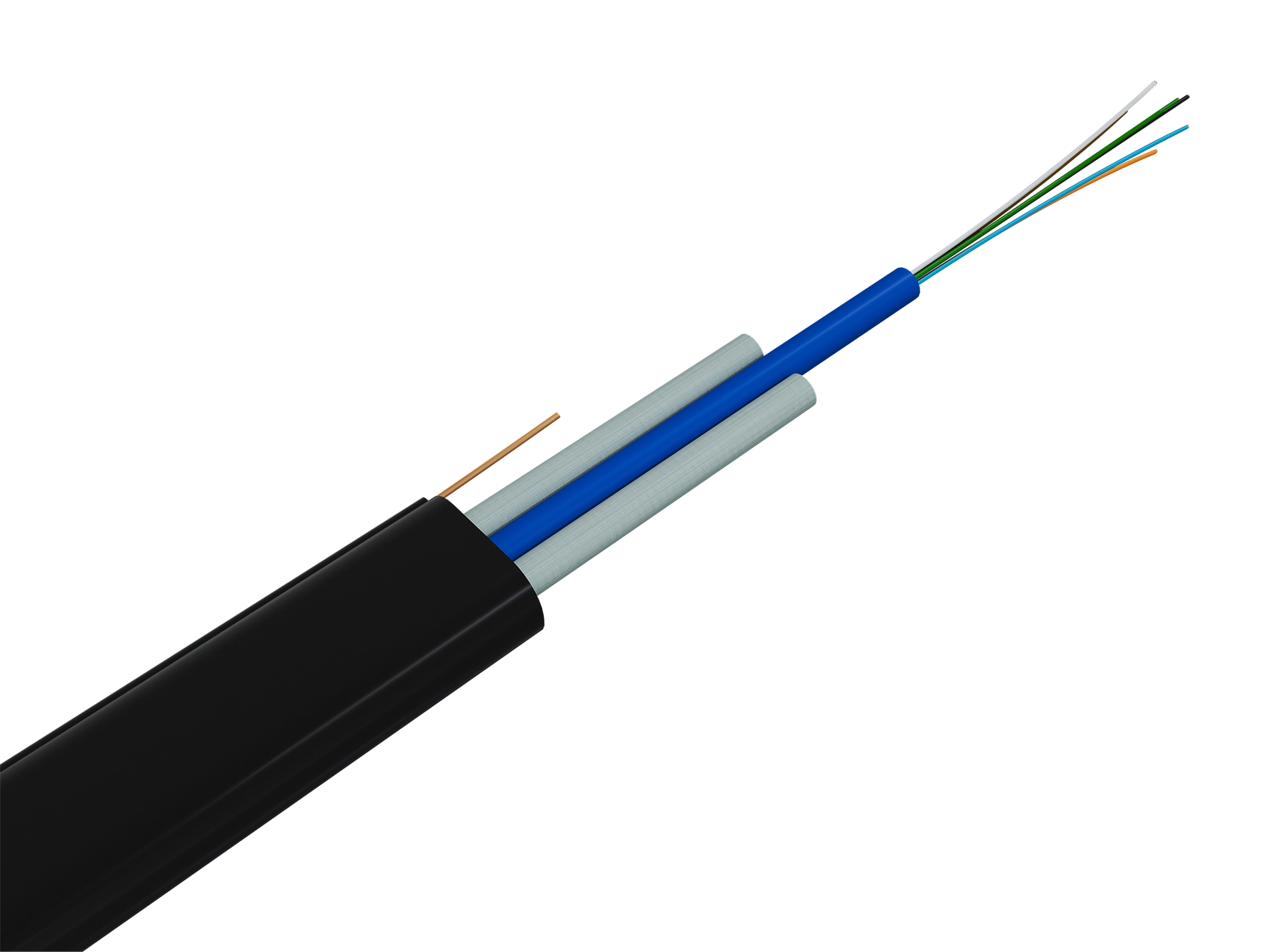

Fiber Optic Drop Cable

Compact, durable, and self-supporting fiber drop cables come in completely all-dielectric or toneable constructions. Reliable and cost-effective for the last link in the optical network, they are the ideal solution for self-supporting aerial, direct buried, and duct FTTx drop installations.

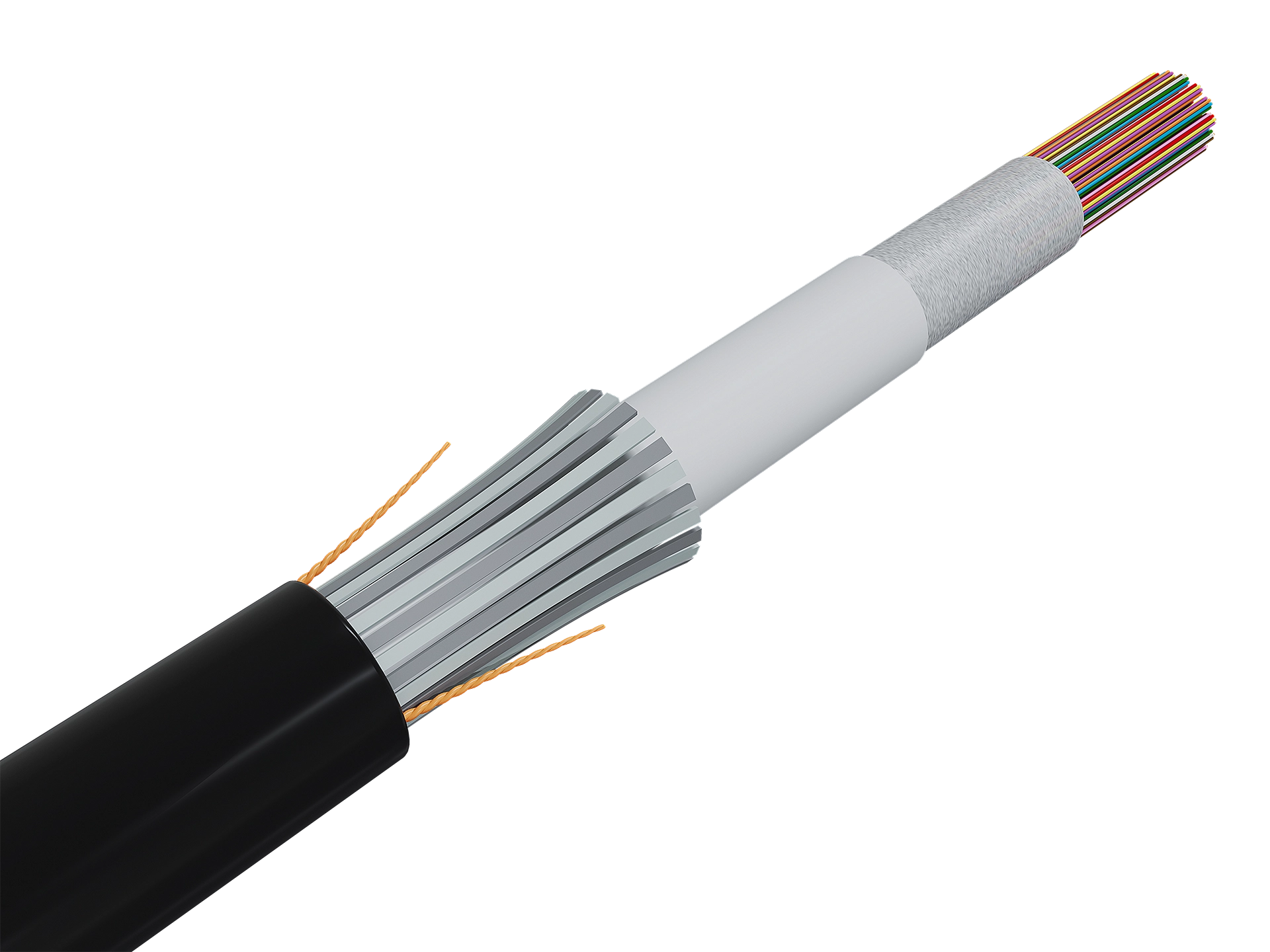

Central Core Cable

Lightera was the first optical cable manufacturer to introduce the central core cable design, offering easy fiber access and maximum fiber density. The central core cables provide excellent optical, mechanical and environmental performance, making them an excellent choice for a wide variety of deployments, including underground conduit and rugged direct burial.

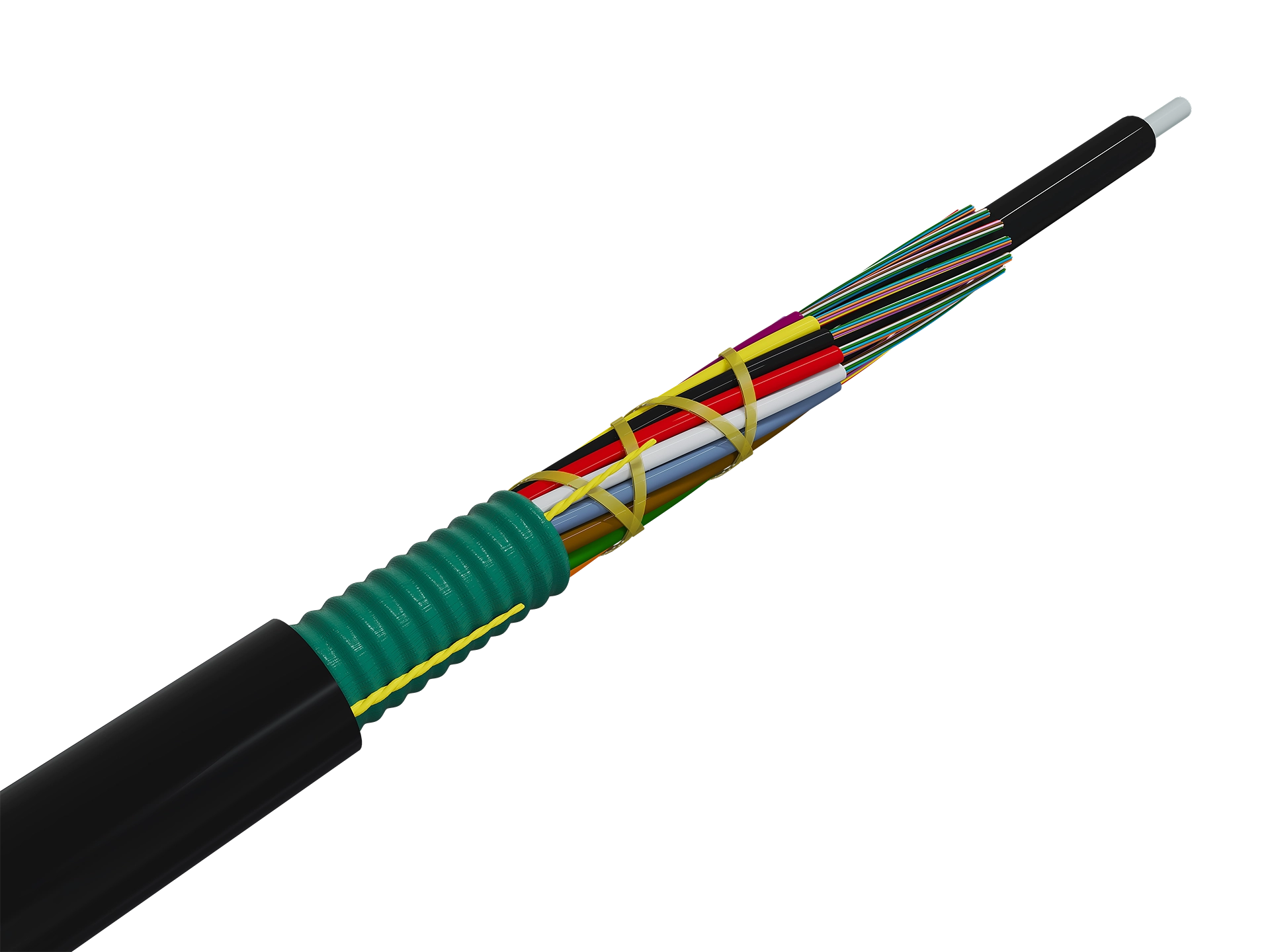

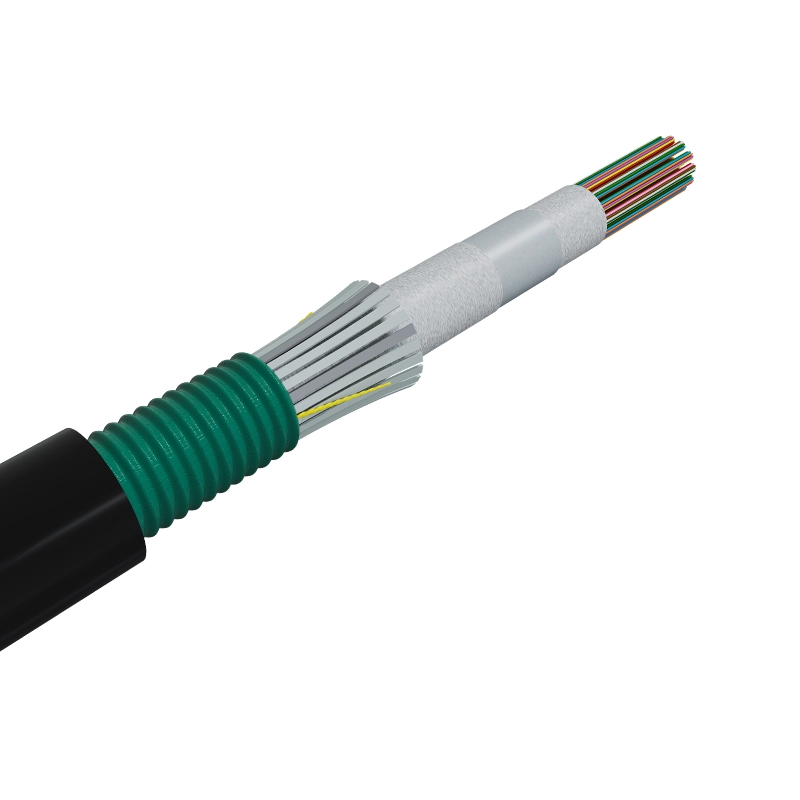

Outdoor/Indoor Fiber Optic Cable

Innovative outdoor/indoor cables combine the flame resistance and safety features of an indoor riser cable with the durability critical for OSP use. The result is a unique, dual-purpose cable that can help save time and money by allowing OSP applications to flow seamlessly indoors, using a single cable and no splices.

Microcables and Air Blown Fiber Units

Lightera microcables and blown fiber units are specifically designed for enhanced air-blown installation where light weight, flexibility and small size are critical. These cables are appropriate for fiber to the home, business, and multiple dwelling unit deployments.

Premises Cable

Lightera premises cables combine peak performance, ease of installation and flexibility with exceptional reliability and safety for a broad range of indoor applications. A full range of high-performance riser, plenum and LSOH-rated low smoke zero halogen cables offer the flexibility to handle virtually any application between building entrance and desktop – in most environments from office to factory floor.

CPR EuroClass Cables

Lightera manufactures cables with CPR EuroClass performance. Click here to see a selection of available products, along with their CPR EuroClass performance.

Specialty Fiber Optic Cables

The advantages of fiber optic cables are well known in the industry:

Performance in Every Environment

These moisture- and fatigue-resistant, industrial indoor/outdoor cables are ideal for harsh environments such as electrical substations and wind turbine towers, and other settings where the cables may need to endure higher temperature conditions or transitions from indoors to outdoors.

Customized Cable Solutions

What sets us apart is our ability to create customized cables from a wide selection of coatings, buffers, and cabling materials to meet specific environmental conditions such as: abrasion, chemical, and solvent exposure, high-temperature, shock, and vibration. The selection of coatings includes:

Whether you need ruggedized industrial fiber optic cables with specialty fibers, reliable moisture and fatigue resistant cables, or versatile indoor/outdoor cables, you can expect a seamless integration, allowing for streamlined operations.

Industrial Indoor/Outdoor Cables

Our approach to specialty fiber optic cables is to build upon these advantages to create solutions for a wide variety of applications where fiber optic cables may need to endure such things as higher temperature conditions, chemical exposure, or transitions from indoors to outdoors. Lightera specialty fiber optic cables serve customers in the medical, manufacturing, commercial and military aircraft, as well as unmanned ground and air vehicles markets.

Discover the Lightera Advantage Today

Lightera is proud to serve the unique needs of applications world wide. We are constantly innovating to meet the demands of innovation. Need help finding the right product for your application, or interested in a customized solution? Reach out to Lightera today.